| Recommended Measured Gas and Range | Recommended Analyzer | Features |

|

H2:0-75% (TCD) CO:0-75% (NDIR) CO2:0-50% (NDIR) CH4:0-20% (NDIR) O2:0-25% (ECD) CnHm:0-5% (NDIR) *C2H4:0-5%(NDIR) *C2H2:0-5%(NDIR) |

Gasboard-3100P | Portable/ RS232/ RS485/ data record/ in-built sampling pump |

| Gasboard-3100 | Rack type/ RS232/ RS485 / 4-20mA output/ data logging | |

| Gasboard-9021 | 7*24 monitoring/ sampling conditioning unit/ PLC control |

Measurement of C2H2, C2H4 are recommended when the feedstock contains plastic, tyre, etc.

| Recommended Measured Gas and Range | Recommended Analyzer | Features |

|

CO: 0-50% (NDIR) CO2:0-50% (NDIR) H2: 0-100% (TCD) CH4: 0-100% (NDIR) |

Gasboard-3100P | Portable/ RS232/ RS485/ data record/ in-built sampling pump |

| Gasboard-3100 | Rack type/ RS232/ RS485 / 4-20mA output/ data logging | |

| Gasboard-9021 | 7*24 monitoring/ sampling conditioning unit/ PLC control |

| Recommended Measured Gas and Range | Recommended Analyzer | Features |

|

CO: 0-50% (NDIR) CO2:0-2% (NDIR) CH4: 0-50% (NDIR) |

Gasboard-9021 | 7*24 monitoring/ sampling conditioning unit/ PLC control |

Steel Making Gas Mixture /Blast Furnace Top Gas/Coke Gas/Converter Furnace Gas

Steel making is a heavy industry that involves the process of producing steel from iron ore, direct reduced iron products, and/or scrap. And Blast Furnaces dominates the production and supply of metallic units for steelmaking. In blast furnace large quantities of gas (top gas, often contains CO CO2 CH4 H2 O2)are formed at the top of the blast furnace as a result of the reduction of iron ore and the combustion of injected coal by injected blast air. Gas analysis system Gasboard-9021 is recommended to optimize the blast furnace process, including reducing the consumption rate of coke and controlling the temperatures inside the furnace.| Recommended Measured Gas and Range | Recommended Analyzer | Features |

|

CH4: (0~30)%(NDIR) CO2: (0~50)%(NDIR) CO: (0~30)%(NDIR) H2: (0~10)%(TCD) O2: (0~5)%(ECD) |

Gasboard-9021 | 7*24 monitoring/ sampling conditioning unit/ PLC control |

| Recommended Measured Gas and Range | Recommended Analyzer | Features |

|

CO:0-100% CO2:0-100% CH4: 0-100% C2H2:0-100% C2H4:0-100% C2H6:0-100% C3H8:0-100% H2:0-100% O2:0-100% N2:0-100% H2S:0-100% |

LRGA-3100 | Rack type/ RS232/ RS485/ 4-20mA output/ data logging |

| LRGA-6000 | 7*24 monitoring/ Sampling& Conditioning unit/ PLC control |

| Recommended Measured Gas and Range | Recommended Analyzer | Features |

| CH4: 0-1000ppm/0-5000ppm/0-1%/0-10%/0-20% | GASTDL-3100 | In-situ/ Explosion-proof/ IP66 |

| O2:0-1%/0-2%/0-5%/0-10%/0-25%/0-21%/0-50% | ||

| CO:0-1000ppm/0-10000ppm/0-3%/0-10%/0-30%/0-60%/0-100% | ||

|

CO:0-60% CO2:0-20% |

||

|

CO:0-100% CO2:0-100% |

| Recommended Measured Gas and Range | Recommended Analyzer | Features |

|

CH4: 0-100%(NDIR) CO2: 0-50%(NDIR) O2: 0-25%(ECD) H2S: 0-9999ppm(ECD) Or H2S:0-9999ppm (UV-DOAS) Or H2S:0-500ppm (UV-DOAS) Or H2S: 0-500-5000ppm(UV-DOAS) |

Gasboard-3200PLUS | Handheld/ USB/ battery/ In-built memory |

| Gasboard-3200UV | Rack type/ long life H2S sensor/ RS232/ RS485 / 4-20mA output/ data logging | |

| Gasboard-3200 | Rack type/ long life H2S sensor/ RS232/ RS485 / 4-20mA output/data logging | |

| Gasboard-3500 | Wall mounted/ ex-proof/ RS232/ RS485/ 4-20mA/data logging | |

| Gasboard-3500UV | 7*24 monitoring/ Ex-proof/long life H2S sensor/ Gasboard-3500/ Multi-Sampling/Conditioning unit |

Remark: The above recommend measurment range are just for reference, if you have your own requirement on measurment component and range, please feel free to diccuss with us for further options.

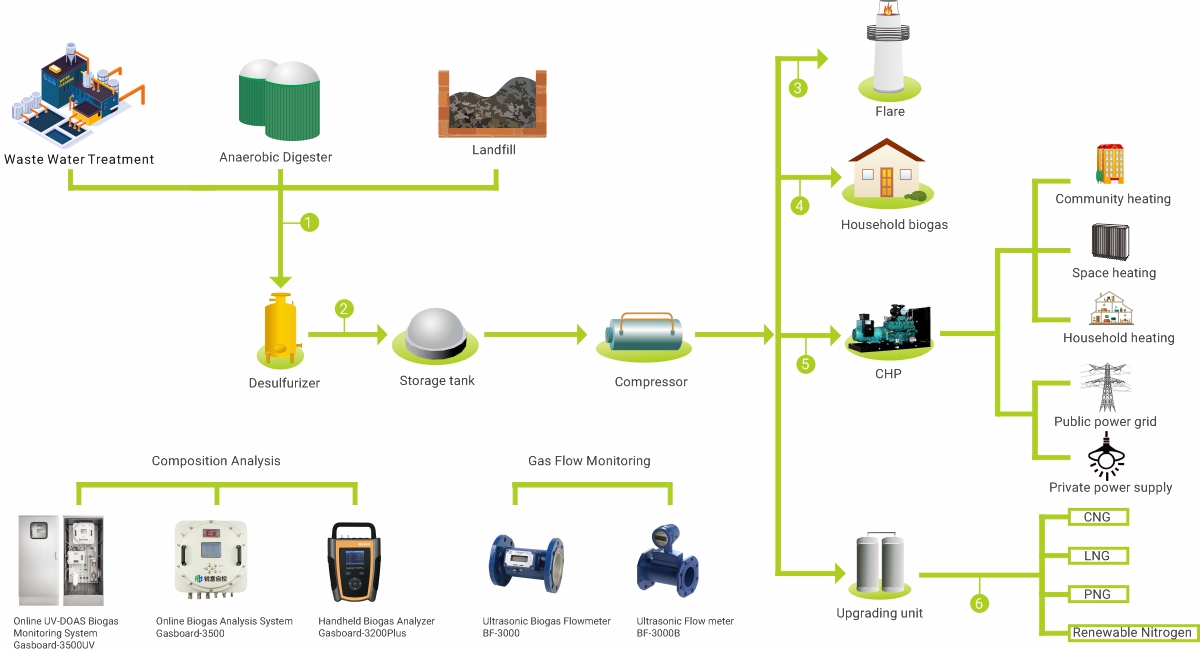

Measurement Points:

1.Downstream of Biogas Digester or Landfill Wells 2.Downstream of H2S Scrubber 3.Upstream of Biogas Flare 4.Upstream of distribution to families 5.Upstream of Biogas Generator/ CHP 6.Downstream of Biogas Upgrading

You can contact Cubic Instruments by telephone or email, or you can submit an online Request for Quotation Form.

For Sales: sales@gasanalyzer.com.cn

For Administration: info@gasanalyzer.com.cn

EMAIL

EMAIL