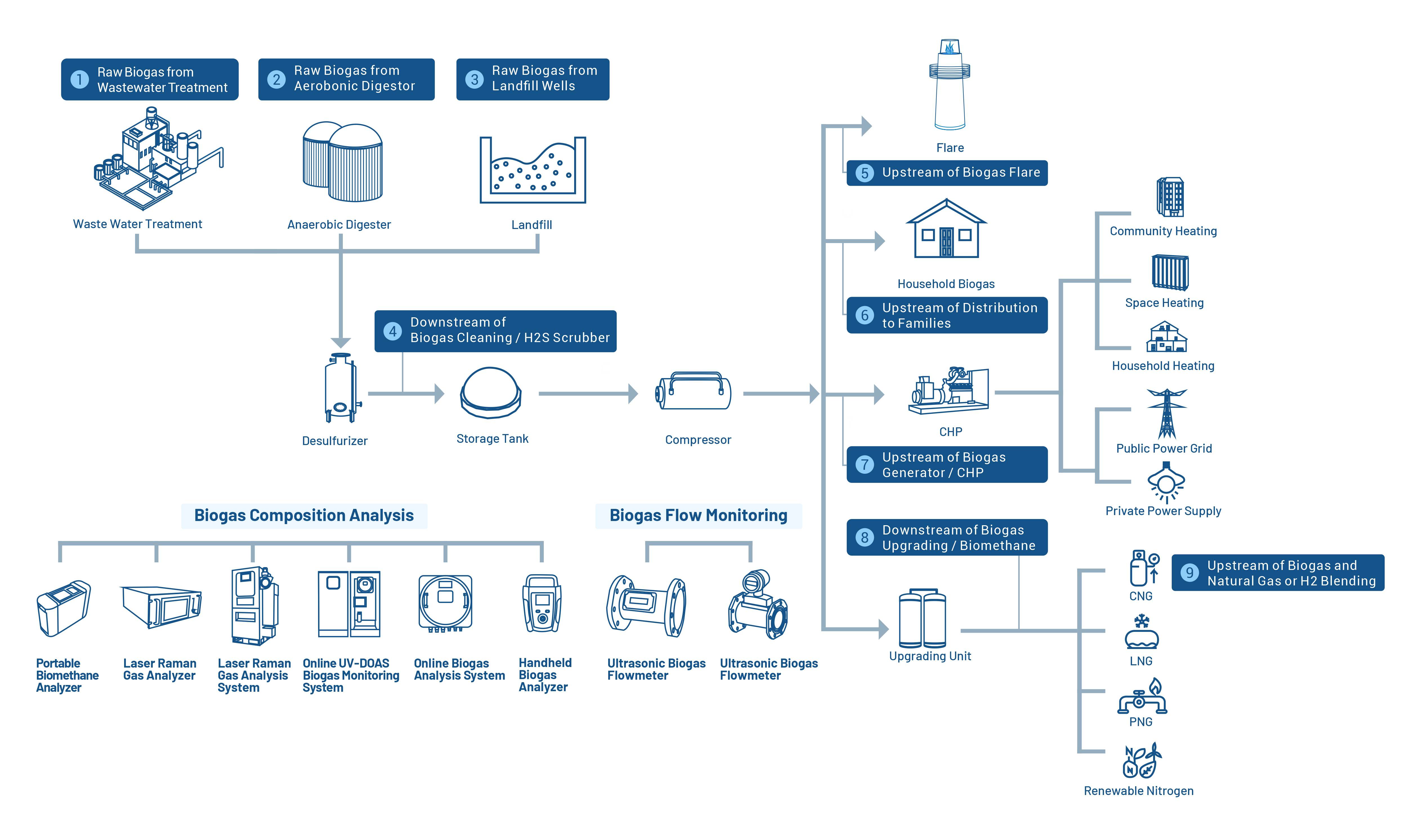

Biogas, a renewable energy source produced from industrial, agricultural, and municipal waste, is gaining increasing global attention. A growing number of anaerobic digestion systems and landfills are being built or planned to produce biogas from wastes such as sugarcane bagasse, alcohol vinasse, palm oil mill effluent, food waste, livestock manure, and wastewater sludge for heat and power generation. To optimize biogas production, prevent potential hazards, and ensure the reliable operation of power and heat engines, it is essential to monitor gas composition in real time throughout the process. From production and treatment to end-use applications, every stage of the biogas value chain relies on accurate gas analysis. With over 20 years of experience in biogas analysis, Cubic Instruments has developed a comprehensive range of biogas analysis instruments, capable of measuring CH4, CO2, H2S, CO, H2, and O2 at various stages of the biogas process.

| Measurement Points | Gas Composition | Gas Analyzer | Flow Meter | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Gasboard 3200plus |

Gasboard 3200L |

Gasboard 3200 |

Gasboard 3200UV |

Gasboard 3500 |

Gasboard 3500UV |

LRGA 3100 |

LRGA 6000 |

BF 3000 |

BF 3000B |

BF 2000 |

|||

| 1 |

Raw Biogas from Wastewater Treatment |

CH4:0-100% CO2:0-25% H2S:0-9999ppm or 0-2.5% O2:0-25% |

● | ● | ● | ● | ● | ● | |||||

| 2 |

Raw Biogas from Aerobonic Digestor |

CH4:0-100% C02:0-25% H2S:0-9999ppm or 0-2.5% O2:0-25% |

● | ● | ● | ● | ● | ● | |||||

| 3 |

Raw Biogas from Landfill Wells |

CH4:0-100% C02:0-25% H2S:0-9999ppm or 0-2.5% 02:0-25% |

● | ● | ● | ● | ● | ● | |||||

| 4 |

Downstream of Biogas Cleaning / H2S Scrubber |

CH4:0-100% C02:0-50% H2S:0-200ppm 02:0-25% |

● | ● | ● | ● | ● | ● | ● | ||||

| 5 |

Upstream of Biogas Flare |

CH4:0-100% C02:0-50% H2S:0-200ppm 02:0-25% |

● | ● | ● | ● | ● | ● | ● | ||||

| 6 |

Upstream of Distribution to Families |

CH4:0-100% C02:0-50% H2S:0-200ppm 02:0-25% |

● | ● | ● | ● | ● | ● | ● | ● | |||

| 7 |

Upstream of Biogas Generator/ CHP |

CH4:0-100% CO2:0-50% H2S:0-200ppm 02:0-25% |

● | ● | ● | ● | ● | ● | ● | ||||

| 8 |

Downstream of Biogas Upgrading/ Biomethane |

CH4:0-100% C02:0-100% H2S:0-20ppm 02:0-25% |

● | ● | ● | ● | ● | ● | ● | ● | |||

| 9 |

Upstream of Biogas and Natural Gas or H2 Blending |

CH4:0-100% C02:0-20% H2:0-100% CnHm:0-20% 02:0-25% |

● | ● | |||||||||

You can contact Cubic Instruments by telephone or email, or you can submit an online Request for Quotation Form.

For Sales: sales@gasanalyzer.com.cn

For Administration: info@gasanalyzer.com.cn

EMAIL

EMAIL