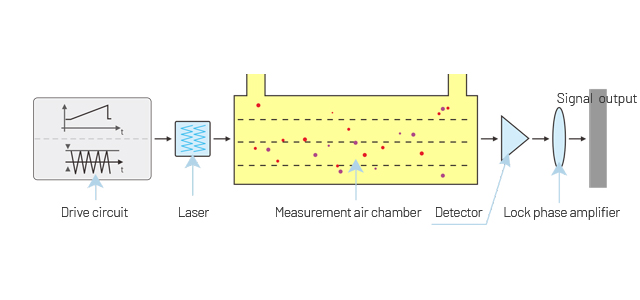

In the realm of gas analysis, Tunable Diode Laser Absorption Spectroscopy (TDLAS) technology stands as a cornerstone innovation, distinguished by its exceptional precision, sensitivity, and reliability. At its core, TDLAS technology harnesses the unique properties of semiconductor lasers - specifically their narrow linewidth and tunability - to perform highly selective molecular gas analysis. The process begins with laser frequency modulation through semiconductor laser current control, allowing a precisely tuned laser beam to interact with gas molecules in process streams or flue ducts. Subsequently, as the target gas selectively absorbs this laser light, the resulting attenuation is measured and processed by a lock-in amplifier, ultimately enabling accurate gas concentration determination through the Beer-Lambert law.

Innovative utilization of TDLAS technology has advanced gas analysis by providing real-time, accurate measurements of gas concentrations. In response to growing industry demands, Cubic Instruments, an international manufacturer of superior gas sensors and gas analyzers, leverages the advanced platform of TDLAS technology and has developed a suite of advanced gas analysis solutions, specifically designed to meet the demanding needs of various industrial applications.

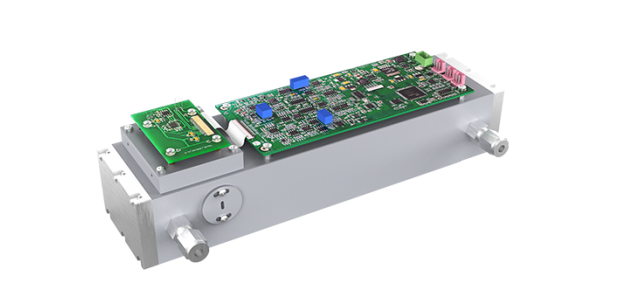

TDLAS OEM Gas Bench:

Cubic Instruments Gasboard-2520 series is a high-performance gas analysis sensor module designed for precise measurement of gases including O2, CO, CO2, H2S or CH4. To ensure maximum accuracy, each module is pre-configured to measure a specific gas within a designated range, from ppm to Vol.% level, with multiple detection ranges available for each gas type. Utilizing TDLAS technology, Gasboard-2520 series combines exceptional sensitivity and high precision, ensuring improved stability and a long lifespan.

Furthermore, a key capability of TDLAS Gasboard-2520 series lies in its narrow-band laser spectrum adsorption method, which effectively eliminates interference from environmental factors including humidity and dust. To further enhance performance in harsh and complex industrial conditions, Gasboard-2520 series is developed with a built-in automatic temperature compensation system, ensuring measurement accuracy despite temperature fluctuations.

The practical implementation of Gasboard-2520 series is facilitated by its RS-232/458 interface and modular design, making it readily integrable into various gas analyzers or existing systems.

With its ability to detect a wide range of gases (O2, CO, CO2, H2S, CH4) and its adaptable measurement ranges, Gasboard-2520 is ideal for numerous applications, from natural gas processing to petrochemical operations and environmental monitoring.

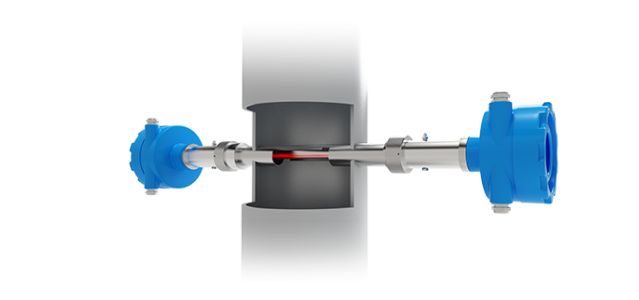

TDLAS In-situ Process Gas Analyzer:

In addition to OEM solutions, Cubic Instruments also offers the advanced gas analyzer, GasTDL-3100, for in-situ process gas measurements. Utilizing highly selective TDLAS technology, GasTDL-3100 advanced gas analyzer accurately measures a broad spectrum of gases including O2, CO, CO2, CH4, H2, H2S, NH3, HF, HCL, and more through in-situ process gas measurements. The analyzer eliminates sampling requirements through direct measurement capability while offering strong anti-interference capabilities. Additionally, GasTDL-3100 maintains high sensitivity across all measured gases, making it an ideal solution for demanding process environments.

While some process gas analyzers often face issues such as long response times and high maintenance and operational expenses due to sampling systems, GasTDL-3100 addresses these challenges with its in-situ, non-contact design, making it suitable for a variety of process conditions, including corrosive, abrasive, and condensing environments. GasTDL-3100 exhibits a high response time of less than 4 seconds during its direct, in-place measurements. Moreover, GasTDL-3100's robust construction, which lacks consumable or moving parts, ensures a long product lifetime and minimizes maintenance costs.

With one or multiple GasTDL-3100 process gas analyzers installed, operators can improve production efficiency and ensure safety process with guaranteed high precision, rapid response, and excellent reliability in various industrial applications.

TDLAS Extractive Gas Analyzer:

Building upon its extensive expertise in gas analysis capability, Cubic Instruments has developed GasTDL-3000 TDLAS Extractive Gas Analyzer, a sophisticated addition to the company's TDLAS gas sensing solution portfolio. GasTDL-3000 system utilizes the highly selective molecular gas analysis principle of TDLAS technology to enable online high-precision monitoring of NH3, HCL, and HF gas concentrations. Compared to alternative detection methods based on electrochemical and infrared technologies, TDLAS technology based GasTDL-3000 system delivers significantly faster response times, realizing real-time monitoring while maintaining exceptional measurement precision.

Specifically designed for optimal performance in industrial applications, the system features a multiple reflection gas chamber design, enabling GasTDL-3000 to detect trace levels of gases and provide ultra-low range measurements. To enhance measurement accuracy in harsh industrial environments, the entire gas flow path is heated to high temperatures, and constructed using low-adsorption materials and advanced processing techniques, thus preventing condensation loss of NH3, HCL, and HF. As a result, the extractive measurement design ensures GasTDL-3000 remains unaffected by dust, temperature, or pressure fluctuations in the flue stream, consistently delivering reliable readings.

Beyond its technical prowess, GasTDL-3000's practical advantages are equally noteworthy. Specifically engineered to withstand harsh environments, GasTDL-3000 demonstrates excellent environmental adaptability, functioning reliably in high-temperature, high-humidity, strongly corrosive, dusty and other harsh industrial environments. Consequently, this robust and efficient solution accurately reflects changes in escaped ammonia concentration, as well as HCL and HF concentrations in real-time, thereby providing reliable data support for environmental monitoring and process optimization.

EMAIL

EMAIL